AI辨識與安全監控

-

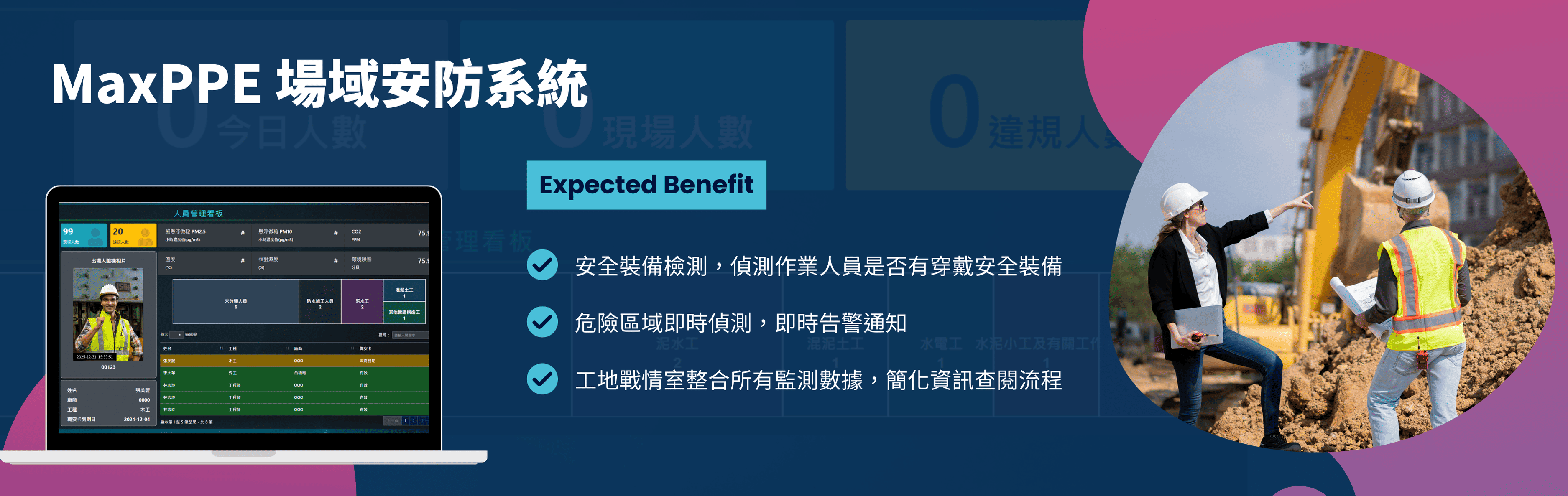

安全裝備檢測

透過AI影像辨識技術,即時監控作業人員是否符合安全規範,若未穿戴必要防護裝備,系統將發出警報。

-

辨識清單

透過即時影像或上傳檔案,即時辨識作業人員安全裝備的佩戴情況,並將結果顯示在辨識清單中。

-

告警清單

系統會將未符合規定的辨識結果顯示在告警清單,供管理人員即時檢視與處理。

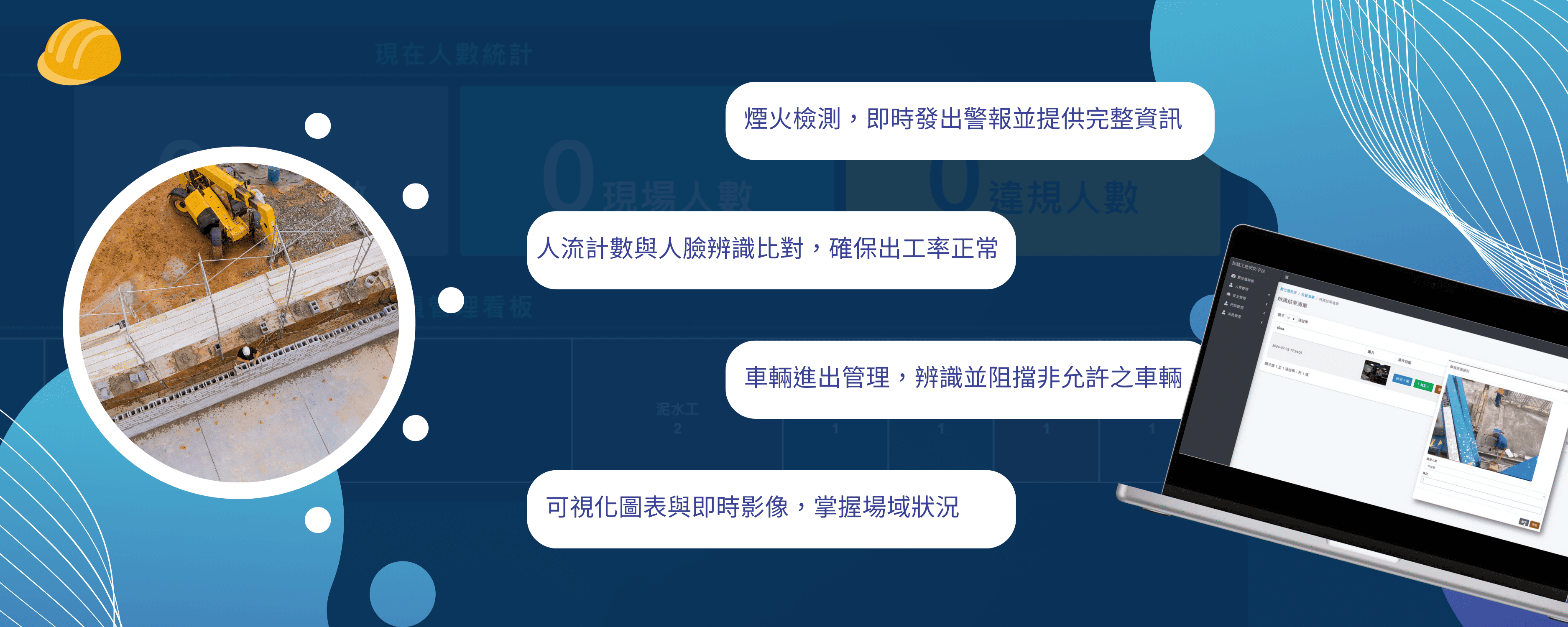

數據監控,讓你放心前行

數據監控,讓你放心前行

裝備檢測,掌握安全

裝備檢測,掌握安全