生產任務與排程管理

-

生產任務排程

即時掌握生產狀態與製程進度,透過製程管理優化生產流程,監控各工序進度,及時調整排程,優先處理逾期生產任務。

-

行動巡查紀錄

透過數位化紀錄,全局掌握生產進度(已完工比例/剩餘工序),即時監控生產流程,確保按時完成訂單交付並提升生產效率。

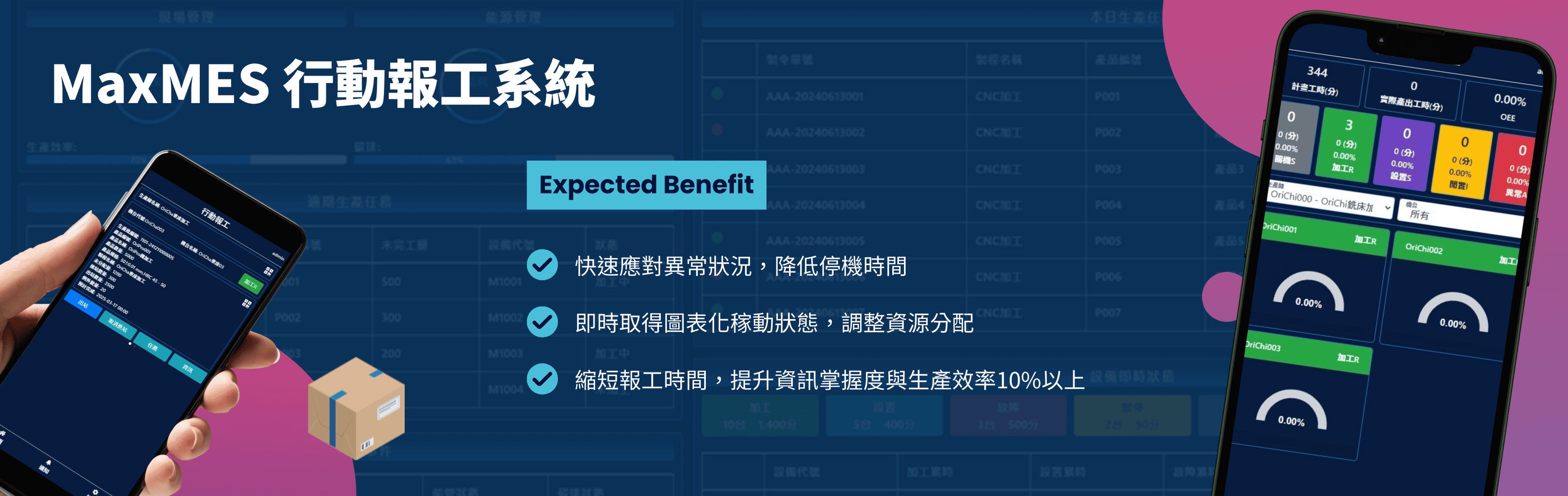

結合智慧製造、ERP 整合與雲端數據分析,MaxMES 提供彈性高效的行動報工解決方案。

報工上雲,可整合 ERP

提升生產效率與低碳智慧製造轉型

提升生產效率與低碳智慧製造轉型

為了提高生產效率並降低錯誤率,我們提供一套數位化、即時的現場管理工具。透過行動設備,操作人員可快速回報生產進度、設備狀態與產量等關鍵資訊,確保生產流程透明化並提升管理精準度。

系統同時支援異常預警、數據同步與自動生成報表,有效幫助企業迅速掌握營運狀況,並即時調整策略以提升產能與品質。

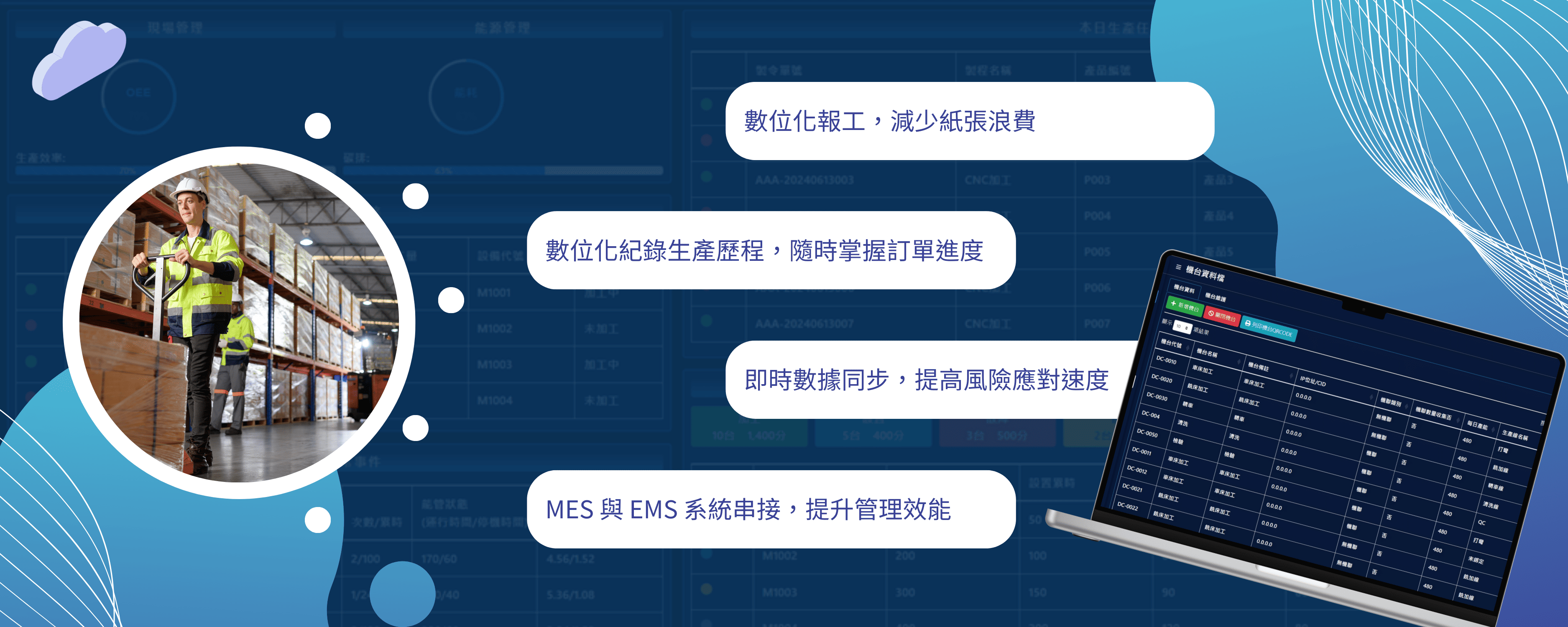

行動報工與數位流程可減少紙本記錄與手動操作,降低能源與資源浪費,實現碳足跡減量,是企業邁向低碳智慧製造的關鍵一步。

系統能自動整合並生成包括生產進度、設備稼動率、產能效率等關鍵報表,協助管理者進行決策分析。

整合設備燈號與感測裝置,於異常情況即時通知管理者,避免生產中斷,並預測維修時機以提升產線穩定性。

透過行動裝置回報現場資訊,管理者能即時掌握產線狀態,強化行動管理與決策即時性。

降低生產成本與浪費

降低生產成本與浪費

優化生產流程,減少物料與能源浪費,同時落實數位化管理,有效降低營運成本並強化 ESG 永續實踐。

提升生產透明度與可追溯性

提升生產透明度與可追溯性

全程數位記錄生產流程,讓每筆工單皆可回溯,提升生產品質控管與客戶信賴度。

即時反應與決策支持

即時反應與決策支持

即時數據回饋讓管理者能立即應對突發狀況,提升現場應變能力與生產靈活性。

即時掌握生產狀態與製程進度,透過製程管理優化生產流程,監控各工序進度,及時調整排程,優先處理逾期生產任務。

透過數位化紀錄,全局掌握生產進度(已完工比例/剩餘工序),即時監控生產流程,確保按時完成訂單交付並提升生產效率。

透過設備燈號即時監控系統,即時顯示設備運行狀態,讓管理者能快速應對異常,提高生產穩定性與維護效率,降低停機風險。

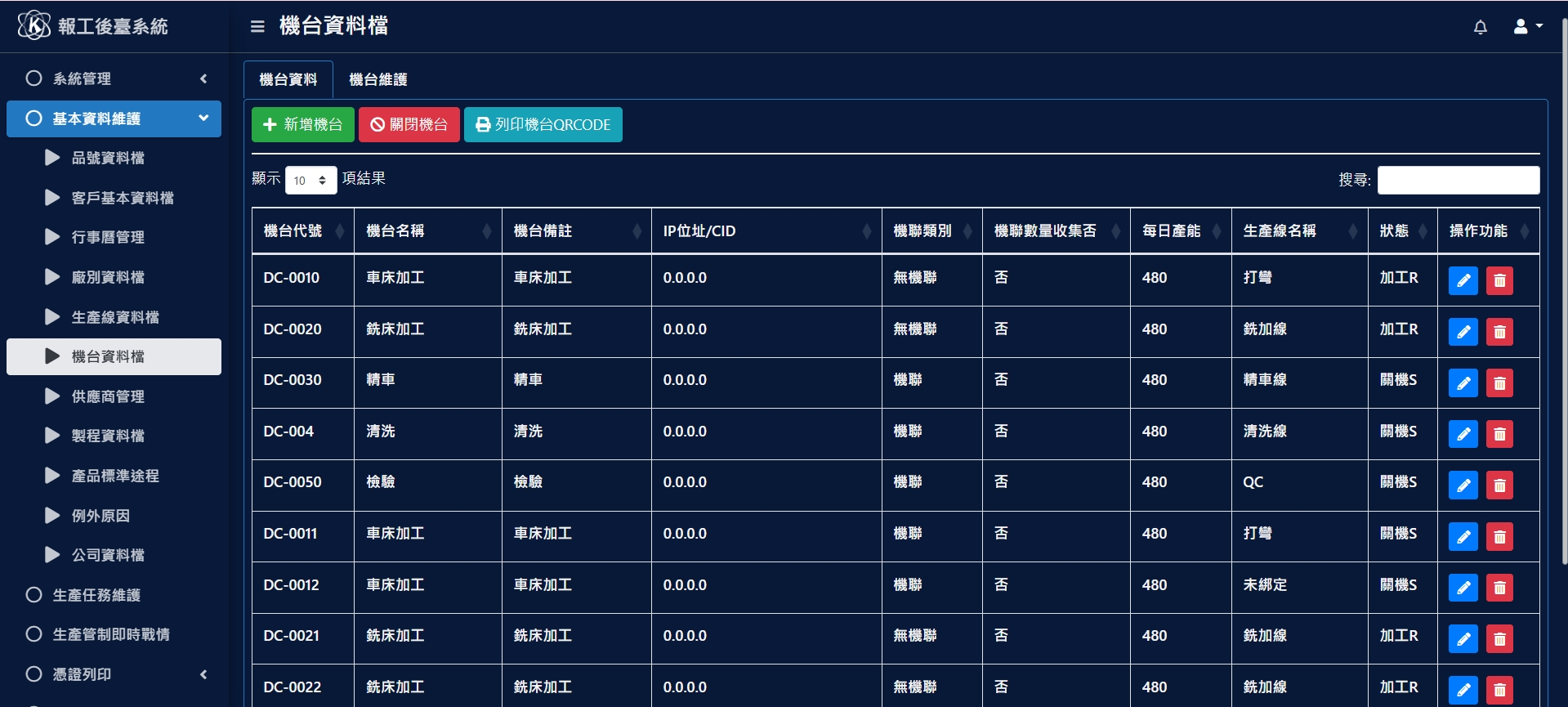

透過機台設置開關與報工系統連動,自動取得設備運行狀態與加工時間,讓管理者提前掌握生產進度與設備使用情況。

整合 AI 演算法分析歷史工單與製程瓶頸,自動辨識潛在異常風險,提前發出預警,協助管理者優化生產排程與資源配置。

全面紀錄並彙整異常事件,提供視覺化回溯報表,輔助持續改善(CI)機制,建立生產流程透明化與標準化的決策基礎。

透過行動裝置掃描工單 QR Code,自動回傳產出數量、設備耗能與碳排放數據,實現即時資料上傳與碳足跡追蹤,提升製造透明度與數位效率。

數位化流程不僅提升生產效率,更符合 ESG(環境、社會、公司治理)原則。

透過圖形化看板展示各項工序的能耗、效率與達成率,提升決策反應速度。

MES 與 EMS 系統同步運作,實現工單、製程與能耗的即時掌控。

快速查詢設備能耗數據,並可視覺化整合歷史資料,利於能源稽核與用電優化。

製造執行系統(MES)與能源管理系統(EMS)雙向整合,強化數據管理、減少浪費、實現智慧製造。

立即聯繫我們,讓專業顧問為您規劃最適合的 MES 智慧生產管理方案, 透過流程整合、提升生產效率與降低能耗,協助企業實現智慧高效低碳製造。